- 4.7

Unmatched Precision and Efficiency

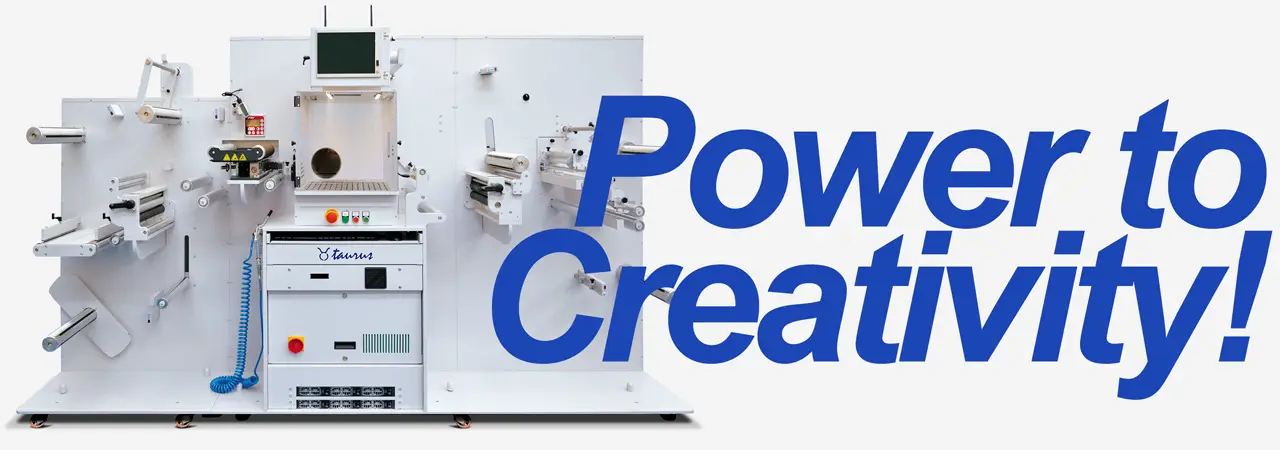

No die tool anymore with Taurus, it is roll to roll digital converting solution powered by a Galvo system technology and equipped with a sealed C02 laser source to finish printed jobs at incredible cutting quality and speed.

Developed on 3 axes scanner and the latest in laser technology, this unit offers a better X and Y register and cut depth control (Z) allowing the user to cut with different power levels on the same labels.

This means an increase in quality and precision of label edges and a higher flexibility in label design supporting multiple laser processes and the laser beam will kiss-cut, slit and perforare most materials used in the label industry.

Working digitally means deliver your jobs just on demand and thanks to the smart features and high speed offered by Taurus the job size, path complexity and work execution of your finished labels will not be a limitation anymore.

TAURUS laser finishers are crafted in Italy, ensuring top-notch quality and performance. Designed to meet the demands of modern label printing, these systems provide exceptional cost savings, operational efficiency, and superior product quality.

Brochure | User Manual TRS25PL |

User Manual TRS35PL |

Why Choose TAURUS?

- Compact Design: Small footprint for easy integration into any workspace.

- Quick Setup: Fast installation and straightforward customization to fit your needs.

- Digital Workflow: Seamlessly integrates with digital workflows for "just-in-time" delivery.

- User-Friendly: No need for highly skilled operators; our systems are intuitive and easy to use.

- Versatile and Fast: Ideal for short runs with high-speed laser cutting on various materials.

- Precision Cutting: Achieve any label shape with top-notch laser cutting quality.

- Efficient: QR code reading for job changes on-the-fly, maximizing productivity.

Benefits:

Advanced Technology for Modern Needs

TAURUS systems support web widths up to 360mm and come in three configurations to meet diverse production requirements. Whether you need standard or custom labels, TAURUS delivers precision and speed, handling materials from paper to plastic films.

Total Digital Workflow

Transition from traditional die-cutting to a fully digital workflow with TAURUS. From PDF to shipping, eliminate tooling and storage costs. The proprietary software integrates with common digital workflows.

Exceptional Service and Support

Our global presence ensures outstanding support during and after purchase. We offer remote assistance and real-time troubleshooting to keep your operations running smoothly.

Environmentally Friendly

TAURUS laser finishers are eco-friendly, reducing material waste and eliminating the need for traditional dies.

| TRS25PL | TRS35PL / TRS35PL-PLUS | |

|---|---|---|

|

|

|

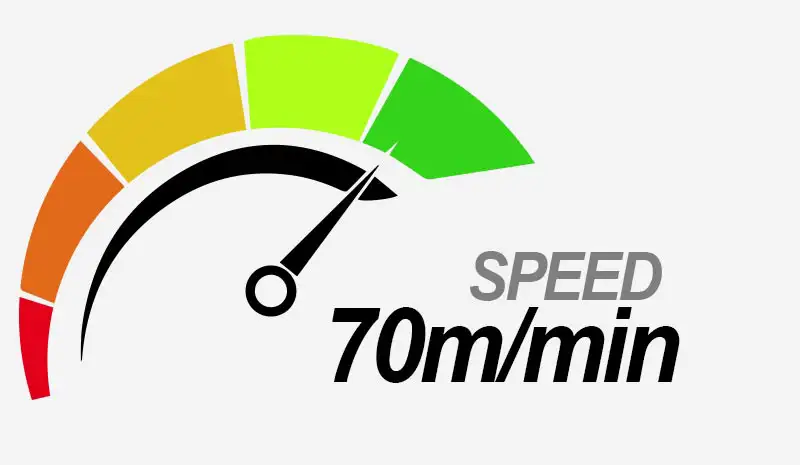

| Cutting Speed | 30m/min | 30m/min (TRS35PL) 70m/min (TRS35PL-PLUS) |

| Input Roll Diameter | up to 500mm (19.68”) | up to 500mm (19.68”) |

| Output Roll Diameter | up to 400mm (15.74”) | up to 400mm (15.74”) |

| Cutting area | 250mm x 250mm (9.84” x 9.84”) |

330mm x 330mm (13” x 13”) |

| Web Width | 50mm - 250mm (1.96” - 9.84”) |

50mm - 350mm (1.96” - 13.78”) |

| Laser Spot Size | up to 250 μm | up to 350 μm |

| Laser Source Power | 150W - 10.25 μm | 350W - 10.25 μm |

| Power Requirement | 220Vac 18A 4000W | 220Vac 34A 7500W |

| Laser Type | Single Head C02 | |

| Type of cut | kiss-cut, full cut, perforation, engraving | |

| Media type allowed | Paper, Plastic Films except PET | |

Brochure

-

-

Up to 70m/min depending on laser power, cut pattern and material being used this finisher offers unwinding, laminating, digital cutting, waste removing, rewinding and length slitting in a single pass.

Type of cut: Kiss-cut, Full cut, Perforation, Engraving

Media type allowed: Paper, Plastic Films except PET

-

-

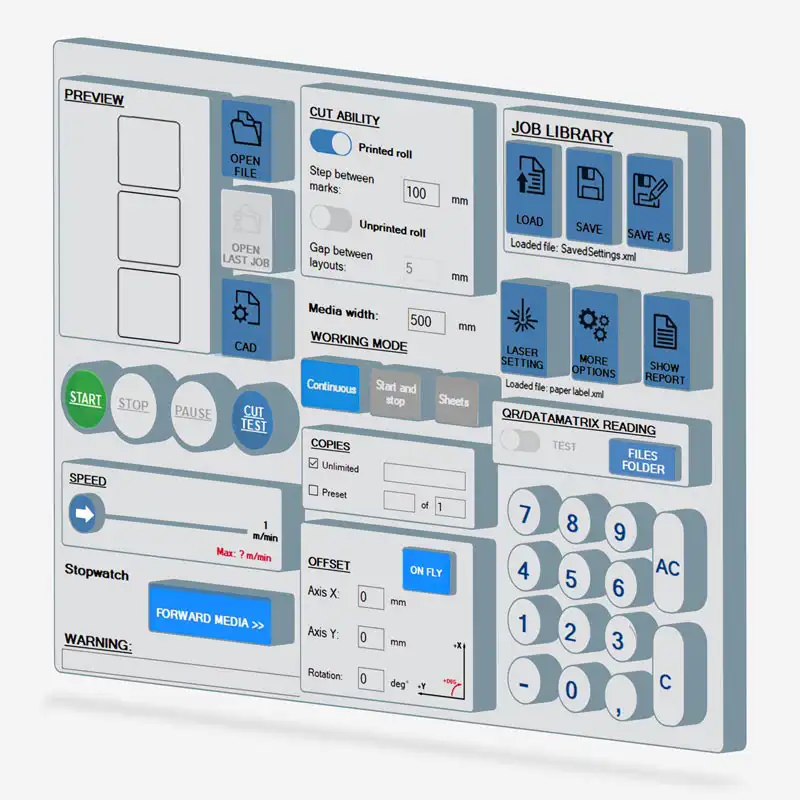

Cutting manager software

An innovative and smart cutting management software allows the operator to easily adjust the work speed and laser output for fabulous cutting, time optimization and less materials waste which in turn = greater profits.

The User friendly management software for Windows is compatible with Adobe PDF files.

-

-

UV Varnish module

Do your paper labels get damaged over time?

Do you want to make them close to being indestructible?

With the cold lamination you see some ugly imperfections on your labels?

With the new UV Varnish module for our laser finishing systems TAURUS, you will FIX this and other problems that could destroy your labels.

Easy to install, practical to use, and it will eliminate the annoying and noisy problem of using foils.