HIGHER LEVEL OF FINISHING FOR YOUR LABELS!

Why?

Applying varnish on labels can make them more resistant to various environmental factors such as moisture, heat, and abrasion. Varnish is a clear or translucent coating that is applied to the surface of the label to provide additional protection.

Which?

There are different types of varnish that can be used on labels, including:

- Gloss varnish: This type of varnish provides a high-gloss finish to the label, which can make it more resistant to abrasion and scratches.

- Matte varnish: This type of varnish provides a matte finish to the label, which can reduce glare and make it more difficult for dirt and fingerprints to stick to the label surface.

- UV varnish: This type of varnish provides additional protection against UV rays, which can cause fading or discoloration of the label over time.

- Scratch-resistant varnish: This type of varnish provides additional protection against scratches and abrasion, making the label more durable.

- Water-resistant varnish: This type of varnish provides additional protection against water, which can cause the label to become smudged or unreadable if it gets wet.

Applying varnish to labels can greatly improve their durability and resistance to environmental factors. It's a great way to add an extra layer of protection to ensure that your labels last as long as possible.

VARNISH MODULES AVAILABLE

| MODELS | Media width | Printing width | Media type |

|---|---|---|---|

| VRN35 (UV Varnish module) | 330mm (13”) * | up to 320mm (12.60”) | Paper, Plastic Films |

| VRN25 (UV Varnish module) | 250mm (9.84") | fino a 240mm (9.45") | Paper, Plastic Films |

(*)215mm wide anylox cylinder available for narrower rolls

-

-

VRNxx - UV Varnish module for Taurus and Aries

The UV varnish module is an accessory available for TAURUS and ARIES, it is a flexographic unit equipped with an anylox cylinder capable of depositing 3.5 grams of varnish per square meter with a semi-gloss finishing (it is possible to order the anylox cylinder with customised finishing specifications).

Installed in-line to the finishing systems, the power of the UV lamp is automatically adjusted according to the laser cutting speed and when the media stops inside it, the protective shutter immediately intervenes.

-

-

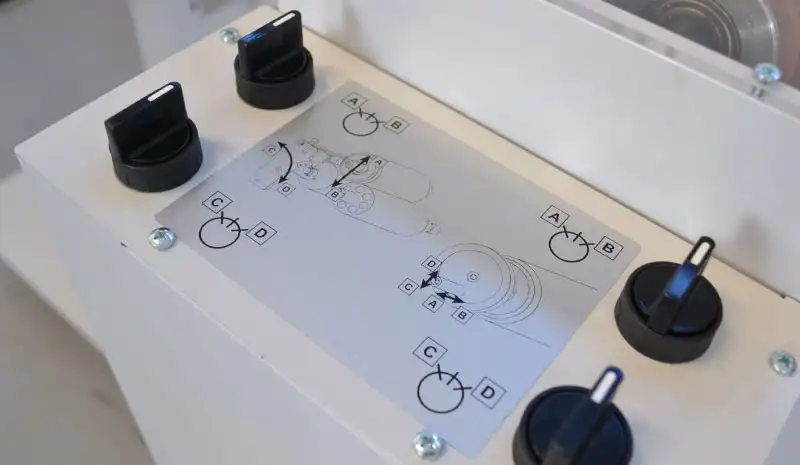

CONTROL PANEL

A user-friendly control panel that makes integrating the varnish module into your system quick and effortless.

-

YOUR LABELS IN-HOUSE

Creating an in-house finishing station for labels can provide companies with greater control, cost savings, and flexibility in the label production process. It can also help to improve the overall quality and longevity of the labels, and increase brand recognition.

Request a Free Call or a Demo live. We are here to support your choise and to delete any doubts. -

VIDEO